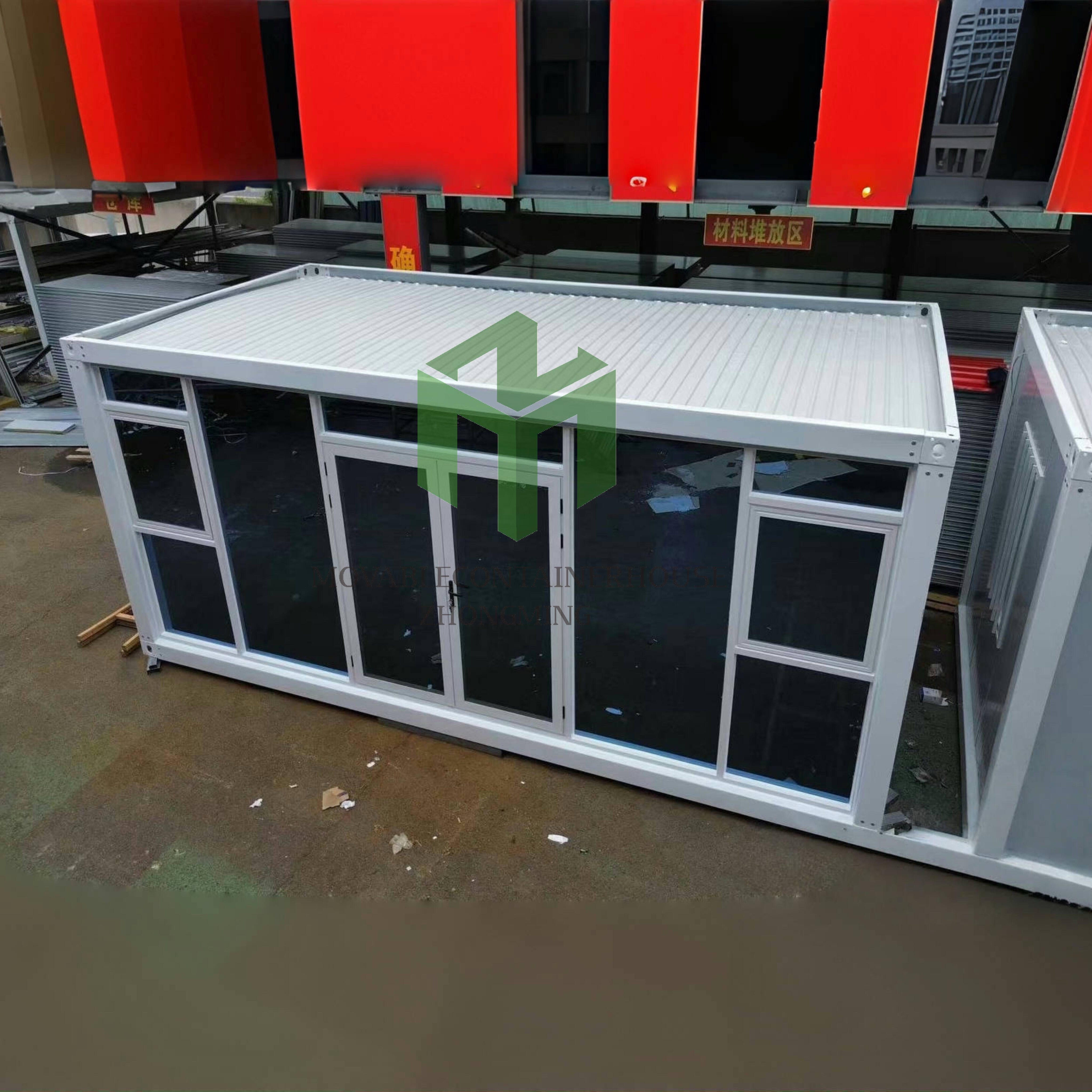

container prefabricated house factory

A container prefabricated house factory represents a modern manufacturing facility dedicated to producing high-quality modular housing solutions. These facilities combine advanced automation technology with precise engineering to create standardized living spaces from shipping containers. The factory operates through multiple specialized production lines, each handling specific aspects of the manufacturing process, from container modification to interior finishing. State-of-the-art equipment, including automated welding systems, CNC machines, and robotic painting stations, ensures consistent quality and efficient production. The facility incorporates quality control stations at every crucial stage, monitoring everything from structural integrity to insulation installation. Advanced design software enables customization of layouts while maintaining manufacturing efficiency. The factory's climate-controlled environment allows year-round production, unaffected by weather conditions. Material storage and inventory management systems ensure optimal production flow, while specialized areas handle electrical, plumbing, and HVAC integration. The facility also features testing areas where completed units undergo rigorous quality and safety inspections before shipment. This systematic approach results in faster construction times, reduced waste, and superior quality control compared to traditional building methods.